Crushed stone from granodiorite

Category:

#2544

Description

Crushed stone from granodiorite is a loose building material. It consists of irregularly shaped granules ranging in size from 5 to 70 millimeters and a larger diameter.

It is made from granodiorite, a dense, full–crystalline rock of igneous plutonic origin of a greenish-gray hue, which was formed as a result of volcanic eruptions. It contains substances that are present in diorite and granite, which makes it intermediate between these two minerals.

There are several main components in the composition:

60-95% plagioclase or oligoclase;

15-25% quartz;

10-25% - alkaline potassium-sodium feldspar;

15% - biotite, pyroxenes, hornblende and hornblende, other ingredients: zircon, sphen, apatite, magnetite.

Unlike granite, this mineral contains An30-50 in plaxioclase, while the proportion of colored minerals can reach 25%. The product is also characterized by quartz xenomorphism in relation to plagioclase.

It is produced by quarrying: the soil is blown up, due to which it breaks into fragments. Then they are transported by dump trucks to a processing plant, where they are crushed to the required size. By sieving through sieves, the product is divided into groups with granules of different sizes.

The finished products must meet the requirements specified in the state standard GOST 8267-93.

Kinds

There are several varieties of the product in terms of mineral content:

augite-hornblende;

biotite-hornblende;

augitic;

biotite;

hypersthenic biotite;

biotite-hornblende-augite;

Pyroxene is hornblende.

Depending on the structure and texture, a mineral can be porphyritic, fine, medium, uniform, coarse-grained, aplitic, pegmatiodic, miarolic, massive, striped, spotted, gneiss-like.

Application

Such crushed stone is used mainly during construction work. It is added to concrete and asphalt mixes, used for arranging cushions under the roadway, as well as for forming foundations under various structures. In the repair of roads, highways and railways, these products are also in demand.

Granite-diorite crushed stone is one of the most common building materials, along with cement, concrete, reinforced concrete and brick.

Due to its high decorative properties, it is often used in the creation of landscape design, decoration of facades and premises.

Classification

It is customary to classify these products by fractions depending on the grain size.

Up to 5 millimeters is a dropout. It is used for the manufacture of concrete products with thin walls, tiles for sidewalks, ceramics, in the filling of playgrounds and footpaths, in the production of dry mixes for construction and decoration.

5-10 millimeters. Fine crushed stone is added to building mixes to improve the ratio of ingredients.

10-20 millimeters. The product is used to create foundations, cushions for road foundations and roads running over bridges, as well as airfield sites.

20-40 millimeters. It is used in the manufacture of reinforced concrete products, in the construction of tram lines.

40-70 millimeters. It is used in the construction of large structures in civil and industrial construction, as well as in the construction of railway tracks.

More than 70 millimeters. It is in demand in finishing works in the construction of swimming pools, reservoirs, fences.

Intermediate variants with granule sizes are also distinguished. 4-5,6; 5,6-8; 8-11,2; 11,2-16; 16-22,4; 22,4-31,5; 4-16 millimeters and others.

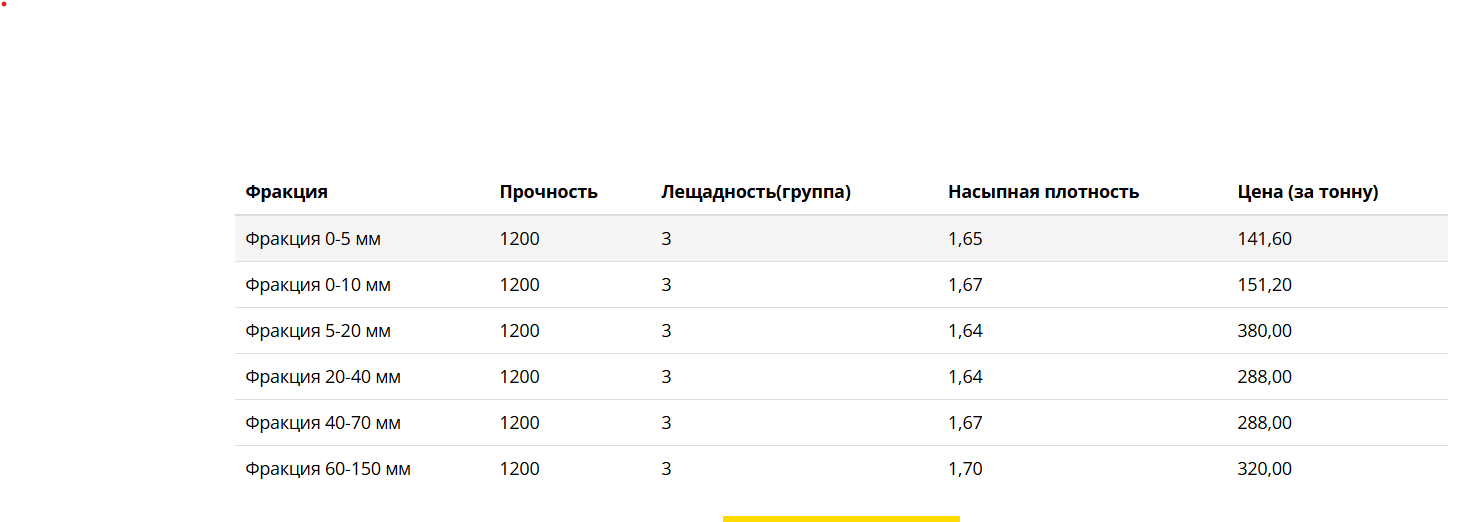

Cost

The price of crushed stone is determined by the size of the granules. The smaller the grain, the more expensive the product is. When calculating price indicators, the quality of products is taken into account.

The cost is affected by shipping costs. Therefore, it is more profitable to purchase such products in the region where the customer is located. In that case, the goods are transported by road. If it is necessary to deliver the product to other regions, a railway connection is used.

Advantages and disadvantages

This mineral has a density of 2700-2900 kg/m3. The strength grade in terms of crushing parameters is M1400, in terms of abrasion – I1, Ib1. In terms of frost resistance, the product belongs to the F400 class.

The bulk density index is about 1400 kg/m3. The larger the grain, the lower the density, as the gaps between the granules increase. The true density is 2600 kg/m3: it is higher due to the fact that the distances between the crushed stone particles are not taken into account in the calculations.

The level of greediness of crushed stone is low, which allows it to be used in many areas of construction and other areas.

The product can withstand up to 300-400 cycles of freezing and thawing without changing the parameters. This indicates a significant level of frost resistance of such crushed stone and makes it possible to use it in regions with extremely low air temperatures.

The performance characteristics of crushed stone of this type are higher than other varieties of crushed stone and artificial analogues. It is a suitable filler for concrete mixes.

Among the disadvantages of diorite-granite crushed stone are high levels of radioactivity. This is due to the presence of thorium and radium, chemical radioactive elements, in the stone. In this regard, before selling products, the manufacturer is obliged to check their radioactivity and provide the buyer with the appropriate certificate.

It is made from granodiorite, a dense, full–crystalline rock of igneous plutonic origin of a greenish-gray hue, which was formed as a result of volcanic eruptions. It contains substances that are present in diorite and granite, which makes it intermediate between these two minerals.

There are several main components in the composition:

60-95% plagioclase or oligoclase;

15-25% quartz;

10-25% - alkaline potassium-sodium feldspar;

15% - biotite, pyroxenes, hornblende and hornblende, other ingredients: zircon, sphen, apatite, magnetite.

Unlike granite, this mineral contains An30-50 in plaxioclase, while the proportion of colored minerals can reach 25%. The product is also characterized by quartz xenomorphism in relation to plagioclase.

It is produced by quarrying: the soil is blown up, due to which it breaks into fragments. Then they are transported by dump trucks to a processing plant, where they are crushed to the required size. By sieving through sieves, the product is divided into groups with granules of different sizes.

The finished products must meet the requirements specified in the state standard GOST 8267-93.

Kinds

There are several varieties of the product in terms of mineral content:

augite-hornblende;

biotite-hornblende;

augitic;

biotite;

hypersthenic biotite;

biotite-hornblende-augite;

Pyroxene is hornblende.

Depending on the structure and texture, a mineral can be porphyritic, fine, medium, uniform, coarse-grained, aplitic, pegmatiodic, miarolic, massive, striped, spotted, gneiss-like.

Application

Such crushed stone is used mainly during construction work. It is added to concrete and asphalt mixes, used for arranging cushions under the roadway, as well as for forming foundations under various structures. In the repair of roads, highways and railways, these products are also in demand.

Granite-diorite crushed stone is one of the most common building materials, along with cement, concrete, reinforced concrete and brick.

Due to its high decorative properties, it is often used in the creation of landscape design, decoration of facades and premises.

Classification

It is customary to classify these products by fractions depending on the grain size.

Up to 5 millimeters is a dropout. It is used for the manufacture of concrete products with thin walls, tiles for sidewalks, ceramics, in the filling of playgrounds and footpaths, in the production of dry mixes for construction and decoration.

5-10 millimeters. Fine crushed stone is added to building mixes to improve the ratio of ingredients.

10-20 millimeters. The product is used to create foundations, cushions for road foundations and roads running over bridges, as well as airfield sites.

20-40 millimeters. It is used in the manufacture of reinforced concrete products, in the construction of tram lines.

40-70 millimeters. It is used in the construction of large structures in civil and industrial construction, as well as in the construction of railway tracks.

More than 70 millimeters. It is in demand in finishing works in the construction of swimming pools, reservoirs, fences.

Intermediate variants with granule sizes are also distinguished. 4-5,6; 5,6-8; 8-11,2; 11,2-16; 16-22,4; 22,4-31,5; 4-16 millimeters and others.

Cost

The price of crushed stone is determined by the size of the granules. The smaller the grain, the more expensive the product is. When calculating price indicators, the quality of products is taken into account.

The cost is affected by shipping costs. Therefore, it is more profitable to purchase such products in the region where the customer is located. In that case, the goods are transported by road. If it is necessary to deliver the product to other regions, a railway connection is used.

Advantages and disadvantages

This mineral has a density of 2700-2900 kg/m3. The strength grade in terms of crushing parameters is M1400, in terms of abrasion – I1, Ib1. In terms of frost resistance, the product belongs to the F400 class.

The bulk density index is about 1400 kg/m3. The larger the grain, the lower the density, as the gaps between the granules increase. The true density is 2600 kg/m3: it is higher due to the fact that the distances between the crushed stone particles are not taken into account in the calculations.

The level of greediness of crushed stone is low, which allows it to be used in many areas of construction and other areas.

The product can withstand up to 300-400 cycles of freezing and thawing without changing the parameters. This indicates a significant level of frost resistance of such crushed stone and makes it possible to use it in regions with extremely low air temperatures.

The performance characteristics of crushed stone of this type are higher than other varieties of crushed stone and artificial analogues. It is a suitable filler for concrete mixes.

Among the disadvantages of diorite-granite crushed stone are high levels of radioactivity. This is due to the presence of thorium and radium, chemical radioactive elements, in the stone. In this regard, before selling products, the manufacturer is obliged to check their radioactivity and provide the buyer with the appropriate certificate.

Email

Phone number

Connection will be made via internet - no charges apply. Microphone access required.

Adding to Favorites

Your comment: