EUROMIX 5/200 Mobile Concrete Batching Plants

Воронеж

and more

29 городов

Offer valid for the following list of cities:

Category:

Special machinery manufacturer:

Model:

Condition:

Not specified

Availability:

Not specified

#30161

Specifications

The EUROMIX 5/200 mobile mini concrete plant is a compact and efficient solution for the production of concrete and mortars directly on the construction site. The main design feature of this plant is that all its key elements such as hoppers, dispensers and mixer are mounted on a common frame. This makes it easy to transport, allowing the plant to be moved both on small trucks and in a standard 20-foot container, which is especially convenient when changing locations frequently.

No special site preparation is required for the installation and start-up of the plant at the production facility. The modular design simplifies the commissioning process: it is enough to connect the equipment to a three-phase 380 V power supply, organize water supply and, if necessary, install an additional module for melting big bags or paper bags with cement. The additional module includes a melting station and a screw conveyor for feeding cement directly into the mixer tank, which allows you to quickly start production.

Installation of the plant takes a minimum time — no more than 2 hours, after which it is ready for operation. The high mobility of the EUROMIX 5/200 allows you to quickly move it between construction sites as needed.

The plant's productivity reaches 3-4 m3/hour, while about 130 liters of the mixture are prepared in one cycle, which takes an average of 90 seconds. This performance allows you to quickly provide construction work with the required amount of concrete or mortar.

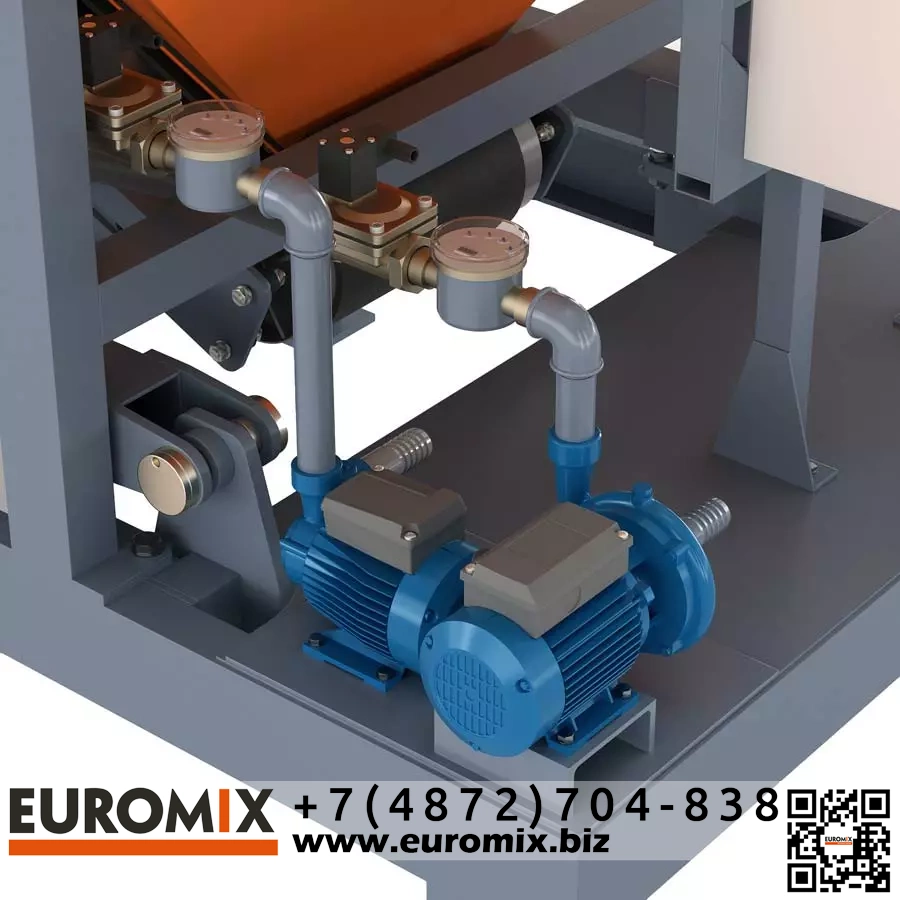

The plant is equipped with one hopper for storing inert materials with a belt feeder that feeds the materials into a rotary mixer. The mixer is mounted on load cells that allow precise weighing of both inert materials and cement. Water supply and addition of liquid components is carried out through volumetric dispensers that ensure accurate dosing. The plant's management system includes automatic and manual modes, which allows both fully automating the production process and manually controlling each stage.

The operator sets the mixing recipe in advance, which takes into account the volume of the mixer, and sets the mixing time. During operation, inert materials are fed from the hopper into the mixer, then cement, water and liquid additives are added. After mixing all the components, the finished mixture is discharged through the mixer gate.

To increase the convenience of operation, a protective grid with a bag breaker is provided on the mixer, which allows you to manually feed materials. This is especially convenient in small facilities or with limited production volumes.

Mixer type / model rotary / EUROMIX 600.200

Capacity up to 5 m3/hour

The total volume of the mixer is 0.2 m3

The volume of the finished mixture (after unloading) is 0.1 m3

The average duration of the mixing cycle is 30-50 seconds

The volume of the inert materials hopper is 2 m3

Overall dimensions (L×W×H) 3070×1590×2600 mm

The installed capacity is 10 kW

Weight 800 kg

No special site preparation is required for the installation and start-up of the plant at the production facility. The modular design simplifies the commissioning process: it is enough to connect the equipment to a three-phase 380 V power supply, organize water supply and, if necessary, install an additional module for melting big bags or paper bags with cement. The additional module includes a melting station and a screw conveyor for feeding cement directly into the mixer tank, which allows you to quickly start production.

Installation of the plant takes a minimum time — no more than 2 hours, after which it is ready for operation. The high mobility of the EUROMIX 5/200 allows you to quickly move it between construction sites as needed.

The plant's productivity reaches 3-4 m3/hour, while about 130 liters of the mixture are prepared in one cycle, which takes an average of 90 seconds. This performance allows you to quickly provide construction work with the required amount of concrete or mortar.

The plant is equipped with one hopper for storing inert materials with a belt feeder that feeds the materials into a rotary mixer. The mixer is mounted on load cells that allow precise weighing of both inert materials and cement. Water supply and addition of liquid components is carried out through volumetric dispensers that ensure accurate dosing. The plant's management system includes automatic and manual modes, which allows both fully automating the production process and manually controlling each stage.

The operator sets the mixing recipe in advance, which takes into account the volume of the mixer, and sets the mixing time. During operation, inert materials are fed from the hopper into the mixer, then cement, water and liquid additives are added. After mixing all the components, the finished mixture is discharged through the mixer gate.

To increase the convenience of operation, a protective grid with a bag breaker is provided on the mixer, which allows you to manually feed materials. This is especially convenient in small facilities or with limited production volumes.

Mixer type / model rotary / EUROMIX 600.200

Capacity up to 5 m3/hour

The total volume of the mixer is 0.2 m3

The volume of the finished mixture (after unloading) is 0.1 m3

The average duration of the mixing cycle is 30-50 seconds

The volume of the inert materials hopper is 2 m3

Overall dimensions (L×W×H) 3070×1590×2600 mm

The installed capacity is 10 kW

Weight 800 kg

Mobile concrete plants

Wholesale prices

0 ₽

Email

Phone number

Connection will be made via internet - no charges apply. Microphone access required.

Leasing/Insurance

Adding to Favorites

Your comment: